We source premium, corrosion-resistant materials to ensure durability.

Every batch undergoes rigorous testing for strength and chemical resistance.

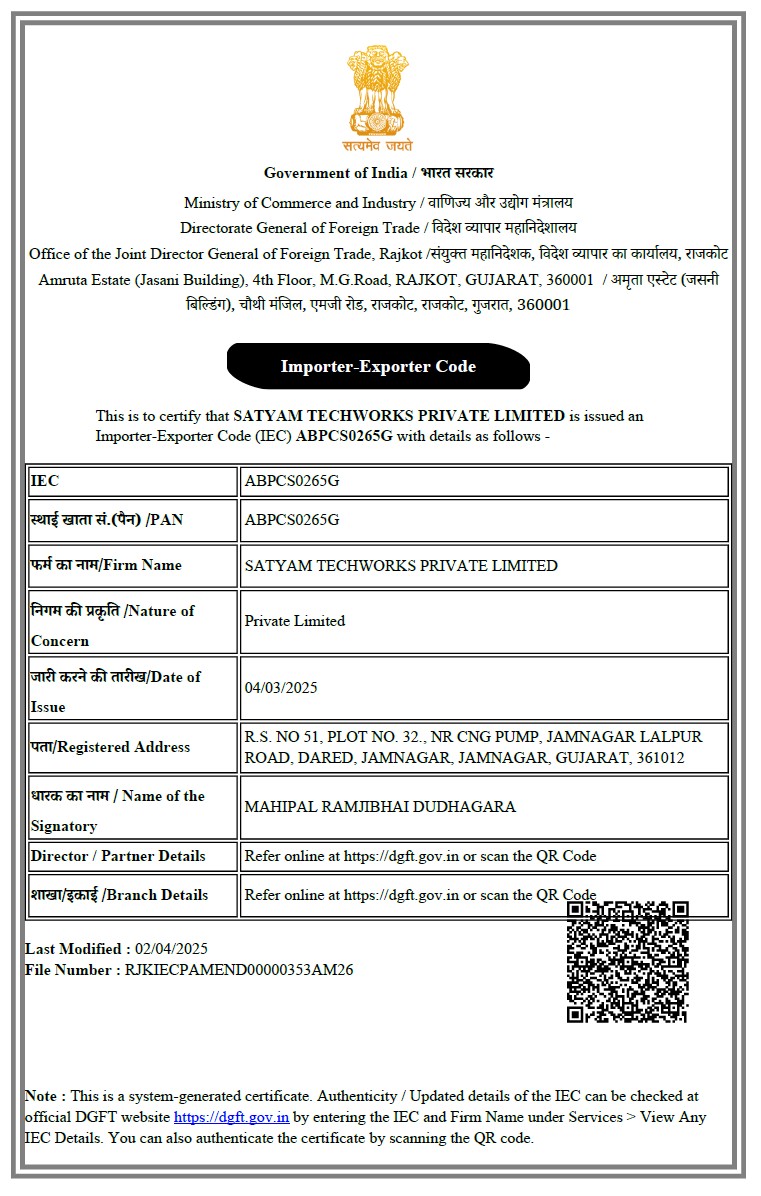

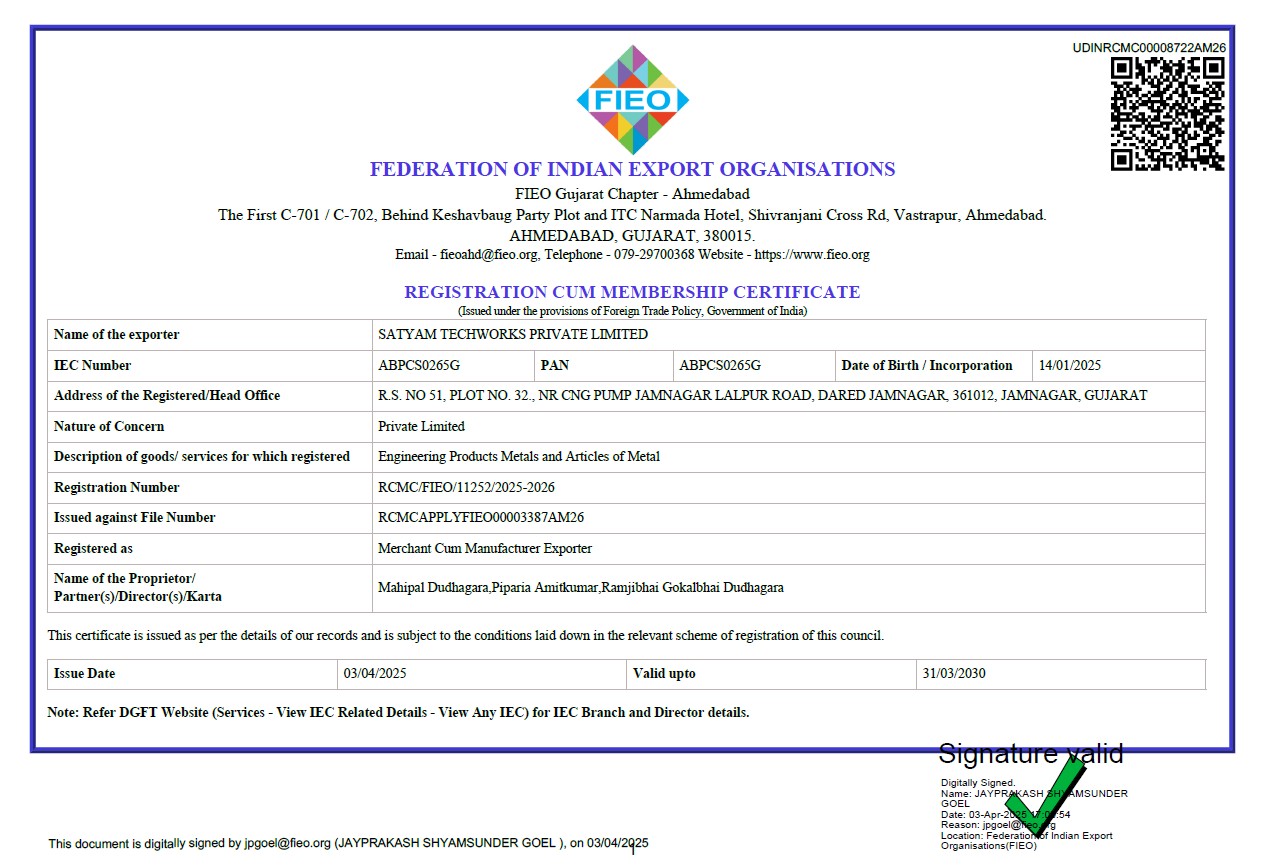

Satyam Techwork Private Limited

An ISO 9001:2015 Certified Company

Quality assurance is the foundation of trust between a brand and its customers. It guarantees that every product meets industry standards, performs reliably, and delivers a seamless user experience.

A strong QA process minimizes defects, reduces waste, and enhances overall efficiency, ensuring that our customers receive only the best.

The primary objective of quality assurance is to deliver defect-free products that meet or exceed customer expectations. To achieve this, companies implement stringent testing protocols, inspections, and quality control measures throughout the manufacturing process.

Consistency in quality ensures that every product delivered to customers maintains the same level of performance, durability, and reliability. This is achieved through standardized manufacturing processes, strict adherence to industry regulations, and continuous quality monitoring.

Customer satisfaction is directly linked to product quality. A well-executed quality assurance program ensures that products meet customer expectations, leading to increased customer loyalty and positive brand perception.

Reducing production inefficiencies and minimizing waste are essential for cost-effective and sustainable manufacturing. By implementing quality assurance measures, businesses can optimize their production processes, reduce material wastage, and improve operational efficiency.

We select premium materials to ensure durability and reliability. Every supplier passes strict evaluations before approval. Rigorous testing is conducted before production starts. Compliance checks guarantee consistent quality standards. This ensures our products remain superior in every aspect.

We use advanced machinery to enhance accuracy and efficiency. Cutting-edge automation reduces human error significantly. Strict protocols ensure uniformity in product quality. Automated systems optimize precision and performance. This results in flawless, high-quality products every time.

Each product undergoes multiple quality checks throughout production. Raw materials are inspected before manufacturing begins. In-process testing detects and resolves defects early. Final testing verifies performance, safety, and reliability. This ensures consistent quality and long-lasting durability.

We strictly follow all industry safety and quality standards. Our products meet ISO, CE, and other key certifications. Regular audits ensure ongoing compliance with regulations. Certification guarantees the reliability of every product. This builds trust and confidence with our customers.

Customer insights drive continuous product enhancements. We analyze feedback to refine design and functionality. Necessary updates ensure improved performance and reliability. Regular innovations help us meet market demands. This approach strengthens customer loyalty and satisfaction.

We source premium, corrosion-resistant materials to ensure durability.

Every batch undergoes rigorous testing for strength and chemical resistance.

Watering Advanced CNC machining guarantees accuracy in all spray gun parts.

Strict quality control ensures uniformity before moving to assembly.

Each spray gun is assembled in a controlled setting to prevent defects.

Nozzle calibration ensures precise spraying with consistent flow.

High-pressure leak tests verify safety and long-term performance.

Endurance testing simulates extended use to ensure durability.

Spray guns are tested with various chemicals for material stability.

Nozzles and seals undergo rigorous exposure tests for reliability.

A final check ensures all products meet strict quality standards.

Secure packaging prevents transit damage and maintains integrity.